Products

BULL FLOATER

A bull float is a long-handled tool with a flat, rectangular blade (typically made of magnesium, aluminum, or wood) used to flatten and smooth concrete after it has been poured. The bull floater is applied to the surface before the final finish to eliminate high spots, fill low areas, and push the larger aggregate down below the surface.

These materials help reduce sticking with wet concrete and are more durable for heavy-duty applications like PQC. The choice depends on factors like durability needs and cost.Chemical agents can be sprayed on the bull float to reduce sticking and improve the smoothness of the finish.After initial bull floating, further passes with finishing blades may be required to achieve the desired surface texture and finish. Extendable handles or extra handle pieces allow operators to reach farther across larger concrete slabs without stepping on or damaging the poured surface.Chemical agents can be sprayed on the bull float to reduce sticking and improve the smoothness of the finish.

Products

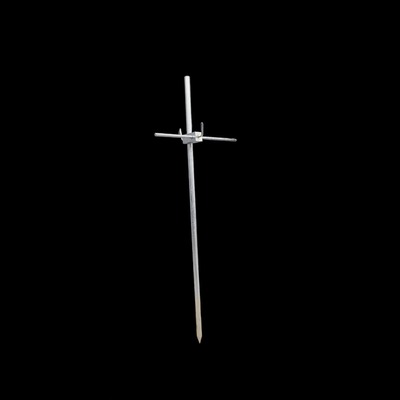

PEG ROD SET

Pegs are driven into the ground at specified intervals to mark the intended concrete level and thickness. They help ensure uniformity across the surface and aid in achieving the design profile. Rods are marked with measurement graduations to set levels precisely.

String lines are often stretched between pegs as a reference to visually guide the height of the concrete. Leveling devices or laser levels may also be used alongside peg rods to ensure precision, particularly for larger or sloped surfaces.After setting pegs to the desired height, straightedges or screeds are used to level the concrete along the reference created by the pegs. This is critical for PQC, where a highly accurate finish is necessary.Wrenches or other small tools may be needed to adjust pegs, particularly if they are adjustable types with threaded bases.

Products

SENSOR WIRE

These wires are embedded within the concrete to monitor curing temperature profiles. Temperature is crucial because it affects the hydration process, setting time, and strength development. A stable temperature can help prevent cracking or other issues in the concrete.

Conduits or sleeves protect sensor wires from damage during concrete pouring and curing. They ensure the wires remain intact and are accessible if adjustments or replacements are needed.Special adhesives or epoxy are often used to bond sensor wires to reinforcement bars (rebars) or secure them in specific positions within the concrete mix. These adhesives should be compatible with concrete and resistant to moisture and temperature changes.

Products

WIRE WINCH

Wire winches are mechanical devices used to pull, lift, or tension wire cables and reinforcement components, which are essential for maintaining structural integrity in PQC work. Below is an overview of how wire winches are used in PQC, as well as the consumables and accessories associated with them.

The cables used with winches are subject to wear and tear due to the heavy loads they bear. For PQC, high-tensile steel cables or galvanized cables are preferred for durability and rust resistance.Clamps and clips are used to secure the ends of the cable and maintain tension. They need to be replaced periodically to ensure a secure grip, as they can wear down or become deformed under high tension.

Products

Separation Membrane / LDPE Sheet For PQC (MORTH Clause.602.5)

| Material | LDPE (Low density Polyethylene) |

| Characteristics | Highly Plastic |

| Thickness | 125 Micron/150 Micron/200 Micron/300 Micron |

| Tensile Strength | 0.32N/MM |

| Notched Impact | No Break |

| Thermal Coefficient of Expansion | 100 -220*10-6 |

| Melting Pint | 110 C (230F) |

| Density | 0.920g/Cm3 |

| Sizes (Width) | 3Mtr,4 Mtr,4.5Mtr,5Mtr,5.5Mtr, 6Mtr, (With Center Sealing 10 Mtr) |

Products

Dowel Bar Cap (MORTH Clause.602.6.5.5)

| Material | Polymer Base |

| Characteristics | Highly Plastic (Thin Plastic Sheath) |

| Thickness | Less Than 0.5 MM |

| Tensile Strength | 13.9 MPa |

| Elongation | 525.4 % |

| MFI of Expansion | 0.91g/10min |

| Melting Pint | 110 C (230F) |

| Density | 0.940g/Cm3 |

| Sizes (Width) | 32*300,32*320,32*350 , 36*300,36*320,36*350 (Other Sizes available As Per Order Quantity) |

Products

Backer Rod (IRC Clause.2011)

| Material | EP Foam Polyethylene Foam |

| Characteristics | Highly Plastic (Foam Based) |

| Color | White |

| Tensile Strength | 213.7 |

| Dimensional Stability | 0.024 |

| Water Absorption | 0.026 |

| Melting Pint | NA |

| Density | 0.024 |

| Sizes (Width) | 6MM,8MM,10MM,12MM, (Other Sizes available As Per Order Quantity) |

Products

Deboning Strip (MORTH Clause: 602.6.5)

| Material | PE Foam One Side Adhesive |

| Characteristics | Highly Plastic (Micro Cellular Foam) |

| Color | Black |

| Tensile Strength | 200 |

| Dimensional Stability | Square/ Rectangles |

| Water Absorption | NA |

| Melting Pint | NA |

| Density | NA |

| Sizes (Width) | All Standard |

Products

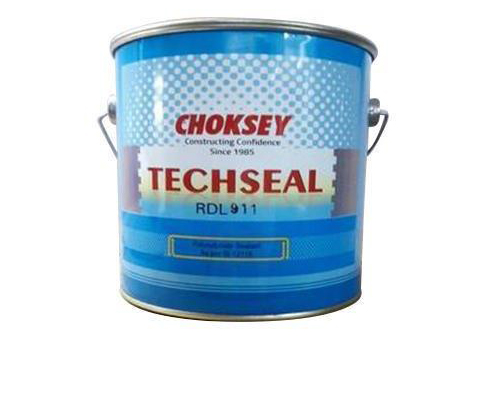

Polysulphide SealantTwo Component Material

PQC or Concrete Road Groove Cutting of Contraction and Expansion Joint in Highways as Per MoRTHStandrd, it is Used in NHAI,MSRDC,PWD and Other Various Infra Projects of Central and State Government Projects.

It is Also Used For Sealing of expansion, contraction & construction joints in building structure such as, buildings, roof terraces & ceilings & Sealing of dynamic structural cracks where maximum movement capability is not more than 20%Glazing joints of window, door frame and curtain wallsSealing of water retaining structure joints such as, Water tank, reservoir, aqua ductsSealing of joints in traffic areas such as industrial floors, and car parking areas.

Products

Jute Bags For Concrete Curing

PQC or Concrete Roads Shall be Cured Using Hessian Cloths ,Jute Cloth for Strengthening Purpose of Concrete.

Curing is the maintenance of a satisfactory moisture content and temperature in concrete for a period of time immediately following placing and finishing so that the desired properties may develop The need for adequate curing of concrete cannot be overemphasized. Curing has a strong influence on the properties of hardened concrete; proper curing will increase durability, strength, water tightness, abrasion resistance, volume stability, and resistance to freezing and thawing and deicers. Exposed slab surfaces are especially sensitive to curing as strength development and freeze-thaw resistance of the top surface of a slab can be reduced significantly when curing is defective.